Zhejiang Tongchao Industry and Trade Co., Ltd., founded in 2006, is a private enterprise specializing in the production and development of rubber and plastic products. Located in Zhejiang Sanmen Bay, about 100 kilometers away from Ningbo Airport, the traffic is very convenient. The total assets of the enterprise is 100 million RMB, covering an area of 10000 square meters.

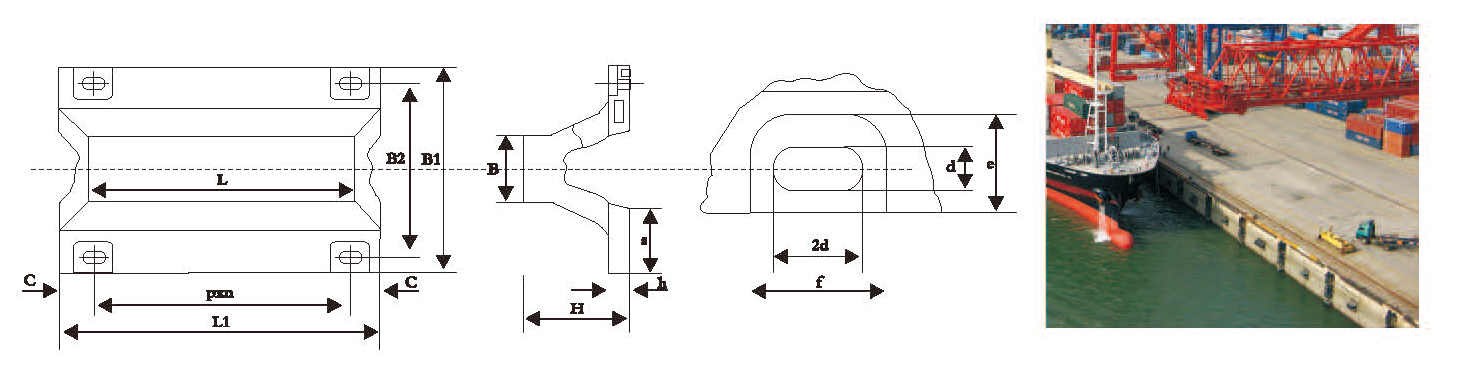

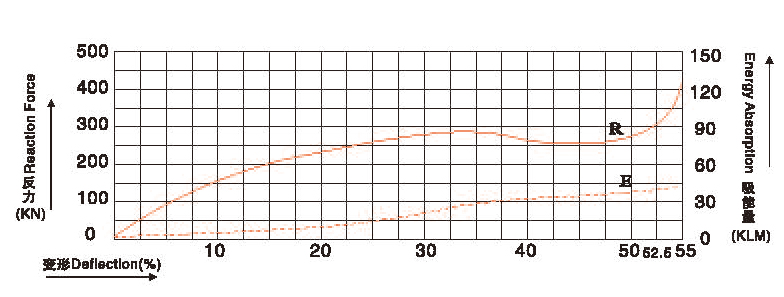

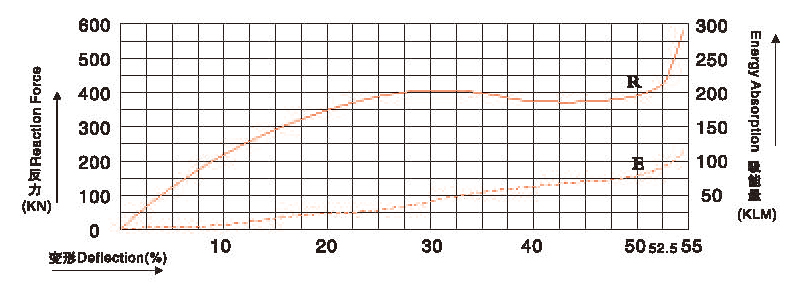

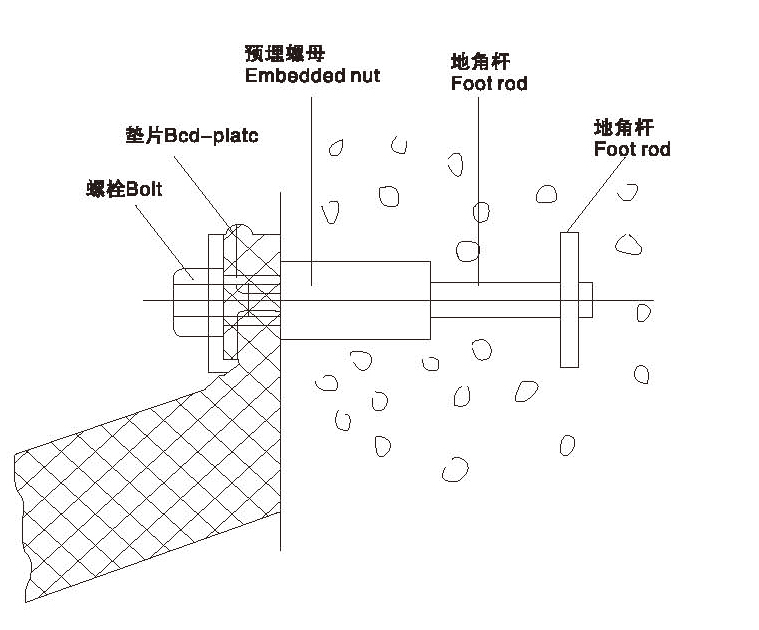

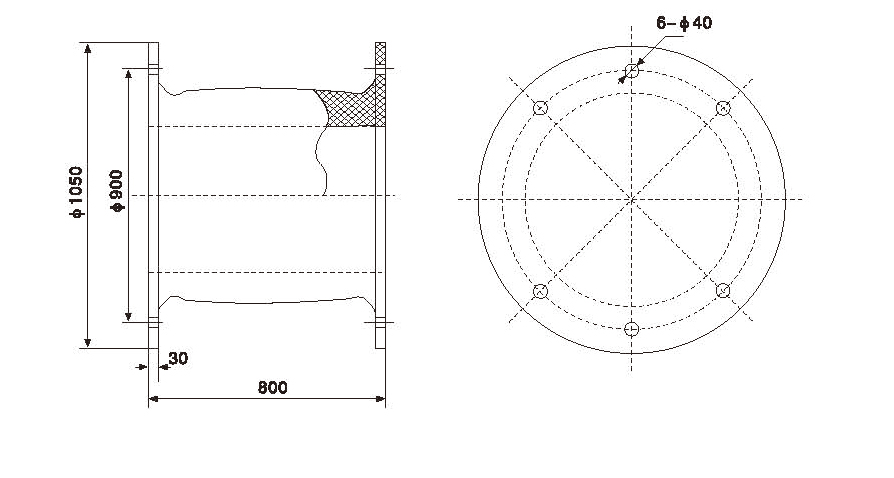

Tongchao as China DA400Hx2000L Pressure Resistance And Impact Resistance Fender For Wharf suppliers and OEM DA400Hx2000L Pressure Resistance And Impact Resistance Fender For Wharf factory, that offers custom DA400Hx2000L Pressure Resistance And Impact Resistance Fender For Wharf for sale with wholesale price. With superior technical team and advanced production line, the company has an annual output of 100,000 pieces rubber solid tires, 200,000 sets rubber fenders and 100000 track meters of railway crossing rubber pads. The DA400Hx2000L Pressure Resistance And Impact Resistance Fender For Wharf products are widely used in steel plant, glass plant, ceramic works, mines, construction, ports, airports, railway construction and military vehicles.

70% of our DA400Hx2000L Pressure Resistance And Impact Resistance Fender For Wharf products are sold in domestic market, and 30% are exported to Europe, America and other international markets. At present, the company has "CHINA QIYU", "HANUAN TIRE" and other independent brands, and has long-term stable cooperation with domestic famous brand manufacturers (China Railway, CCCG, Hangcha, Lonking and other groups), and has established good cooperative relations.

We are willing to cooperate with enterprises and institutions for common development and make contribution to the development of the world rubber industry. Welcome friends to visit, guide and business negotiation.

English

English 中文简体

中文简体