A cell fender is a type of rubber fender commonly used on marine and offshore structures to absorb energy and protect ships and structures from damage during berthing and mooring. Some advantages of battery fenders include:

1. High Energy Absorption: Due to its unique design, the battery fender can absorb a large amount of energy, which helps reduce impact and prevent damage to the ship and the fender itself.

2. Durability: The battery fenders are made of a high-quality rubber compound that is resistant to abrasion, weather, and other environmental factors, making them durable.

3. Versatility: Unitary fenders can be used in a wide range of applications from small pleasure boats to large container ships, as they are able to be customized in different sizes and shapes to suit various vessels and structures.

4. Low maintenance: Unit fenders require minimal maintenance compared to other types of fenders, which helps reduce maintenance costs and downtime.

5. Easy to install: Unit fenders are easy to install and can be quickly replaced if necessary, helping to reduce downtime and improve port operation efficiency.

Overall,

cell fenders are a reliable and cost-effective solution for protecting ships and structures in marine and offshore environments.

1. Cylindrical battery fenders: These are the most commonly used type of battery fenders and consist of a cylinder with a hollow center. They can be installed horizontally or vertically, and their simple design makes them easy to manufacture and install.

2. D-shape unit fenders: These fenders are designed to fit in the corners of piers and docks, the fenders are shaped to match the contours of the hull. D-shaped fenders provide more protection for boats and the corners of docks.

3. Conical unit fenders: These fenders have a conical shape and are usually used on ships with large bow flares. They are designed to distribute the impact of the vessel evenly across the fenders, thereby reducing the risk of damage to the vessel.

4. Rectangular Cell Fenders: These fenders are designed for use on piers and docks where boats are moored parallel to the dock wall. They are often combined with other fender types to provide comprehensive protection for the vessel.

5. W-shaped unit fenders: These fenders have a W-shaped cross-section designed to provide high energy absorption and low reaction forces. They are typically used in small to medium containers.

Overall, the different forms of compartment fenders provide the flexibility to choose the best design according to the specific requirements of the application.

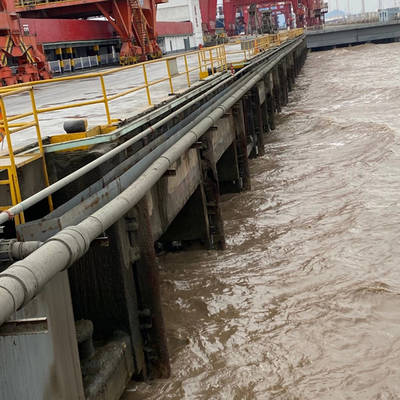

1. Ports and Ports: Unit fenders are commonly used in ports and harbors to protect ships from damage during berthing and mooring. They can be installed on quay walls, breakwaters, and piers to protect against impact forces from incoming vessels.

2. Offshore platforms: Unit fenders are used on offshore platforms, such as oil rigs and wind farms, to protect support, and supply ships during docking and mooring. They can be used on the platform itself or on support vessels and barges.

3. LNG receiving terminal: LNG (liquefied natural gas) receiving terminal uses unit fenders to protect the LNG carrier during loading and unloading operations. They provide cushioning to absorb the impact of the vessel on the dock.

4. Naval Ships: Fenders are used on naval ships, such as warships, to protect them during docking and mooring operations. They can be mounted on dock walls or on other naval vessels.

English

English 中文简体

中文简体