A

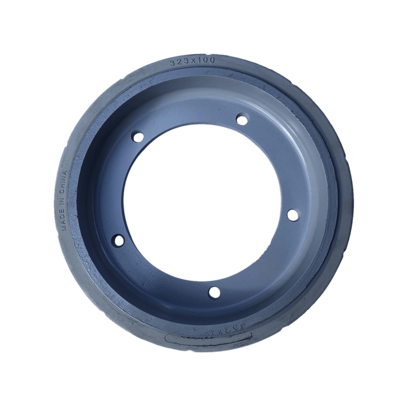

solid tire is a tire that does not contain any air. Rather than an inflated inner tube, tires are made of a solid material such as rubber, polyurethane, or foam. Solid tires are often used in applications where punctures or leaks can cause major problems, such as heavy equipment, forklifts, wheelbarrows, and bicycles.

What Is The Difference Between Solid Tires And Tubeless Tires?

Solid tires and tubeless tires are two different types of tires used on various vehicles. The main difference between these two types of tires is their construction and function.

Solid tires, as the name suggests, are tires made entirely of solid rubber. They don't have any air chambers, so don't need any tubes to hold the air. Solid tires are often used in applications where blowouts and blowouts are a common problem, such as forklifts, golf carts, and carts. Solid tires are very durable and long-lasting, but they don't provide the same level of cushioning as pneumatic (pneumatic) tires.

Tubeless tires, on the other hand, are tires without a tube. The tire itself is made of an airtight material, and the air is kept inside by a seal between the tire and rim. Tubeless tires are commonly used on bicycles, motorcycles, and cars. They offer several advantages over traditional tube tires, including less rolling resistance, better puncture resistance, and a lower risk of punctures. However, they require more maintenance than solid tires and can be harder to fix in the event of a puncture.

To sum up, the main difference between solid tires and tubeless tires is that solid tires are made of solid rubber and have no air chamber, while tubeless tires are made of airtight material and do not require an inner tube to contain the air. Solid tires are usually used in Heavy Duty Applications for Blowouts and Blowouts

1. Forklift tires: Solid tires are commonly used for forklifts and other industrial equipment. These tires are long-lasting and can handle heavy loads and rough terrain.

2. Trolley tires: Trolleys and other small carts also use solid tires. These tires are usually made of a durable rubber compound and are puncture resistant, which makes them ideal for use on construction sites and other harsh environments.

3. Scooter tires: Solid tires are commonly used on scooters and other types of personal mobility devices. These tires provide a smooth ride and require little maintenance.

4. Bicycle tires: Although solid tires are not as widely used on bicycles as they are on other types of equipment, there are some solid tires available for bicycles. These tires are usually made of a hard rubber compound and are a puncture-resistant alternative to traditional bicycle tires.

5. Mower tires: Some lawnmowers come with solid tires, which last a long time and are less prone to blowouts than pneumatic tires.

Overall, solid tires are a popular choice for a variety of applications where durability, puncture resistance, and long life are important factors.

Industrial Equipment: Solid tires are often used on industrial equipment such as forklifts, skid steer loaders, and other heavy machinery. These tires can withstand heavy loads and rough terrain, making them a popular choice for industrial applications.

Construction Sites: Solid tires are great for use on construction sites, where flats and punctures are a common problem. They provide a stable base that helps reduce the risk of downtime due to tire problems.

Warehousing and distribution centers: Warehousing and distribution centers often use solid tires, forklifts, and other heavy equipment for moving heavy loads. These tires can hold the weight of the load and provide a long life, reducing the need for frequent tire changes.

Personal Mobility Devices: Solid tires are commonly used in scooters, power wheelchairs, and other types of personal mobility devices. They provide a smooth ride and are virtually maintenance-free, making them ideal for those who depend on these devices for their daily mobility.

Lawnmowers and other outdoor equipment: Solid tires are also used on lawnmowers, carts, and other outdoor equipment. They are less prone to punctures and blowouts than pneumatic tires, making them a good choice for outdoor use.

Overall, solid tires are good for any scenario where durability and longevity are important factors. They can provide a reliable, low-maintenance alternative to traditional pneumatic tires in a variety of applications.

English

English 中文简体

中文简体